High-Pressure Die Casting Services in Ahmedabad, Gujarat

At Sejasmi, we are at the forefront of advanced metal casting, offering specialized High-Pressure Die Casting (HPDC) services from our state-of-the-art facility in Gujarat. As a leading aluminium die casting manufacturer in Gujarat, we deliver highly precise, complex, and high-volume components that meet the stringent demands of modern industries. Our expertise in aluminium high pressure die casting ensures superior surface finish, tight tolerances, and exceptional material properties for your critical parts.

The Power of High-Pressure Die Casting

High-Pressure Die Casting is a highly efficient and versatile manufacturing process used for producing metal parts by forcing molten metal under high pressure into a steel mold cavity (die). This method is particularly well-suited for non-ferrous metals like aluminium, zinc, and magnesium, and is a cornerstone of modern mass production.

The HPDC process, a core offering at Sejasmi, typically involves:

- Die Preparation: The steel dies (molds) are precisely machined to the desired part shape, preheated, and lubricated.

- Molten Metal Injection: Molten aluminium is rapidly injected into the die cavity under extreme pressure. This high pressure ensures that the metal completely fills even the most intricate features of the die.

- Solidification: The metal quickly solidifies under pressure, ensuring a dense microstructure and excellent surface integrity.

- Ejection: Once solidified, the die opens, and the cast part is automatically ejected.

- Trimming & Finishing: Excess metal (flash, gates, runners) is trimmed, and parts may undergo further processes like shot blasting, machining to achieve final specifications.

Applications of Aluminium High-Pressure Die Cast Parts

The versatility and efficiency of high-pressure die casting make it indispensable across a multitude of industries.

- Automotive Industry: Engine blocks, transmission housings, gearboxes, brackets, and structural components that benefit from lightweight and high-strength aluminium die casting.

- Electronics & Telecommunications: Heat sinks, chassis, connectors, and housings for electronic devices due to aluminium’s excellent thermal and electrical conductivity.

- Appliance Manufacturing: Components for washing machines, refrigerators, and other consumer goods requiring durable and aesthetically pleasing parts.

- Industrial Equipment: Pump housings, valve bodies, and various machinery parts that demand precision and strength.

- Medical Devices: Housings and intricate components where high precision and consistent quality are critical.

Why Choose Sejasmi

Expertise & Precision

With deep metallurgical knowledge and advanced gravity die casting techniques, we deliver high-quality results even for complex projects.

Modern Infrastructure

Our Rajpur facility is equipped with state-of-the-art machines, precision controls, and rigorous quality checks to ensure world-class standards.

Customized & Complete Solutions

From tailored casting designs to value-added services like heat treatment and shot blasting, we provide end-to-end aluminium casting solutions under one roof.

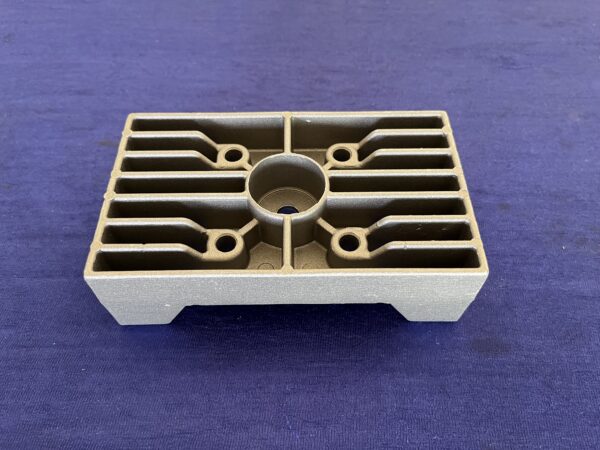

Product Gallery

How does high pressure die casting differ from gravity die casting?

High pressure die casting uses force to inject molten aluminium into molds, while gravity die casting relies on natural gravity flow.

What are the benefits of high pressure die casting?

It allows for mass production, thin-walled parts, and excellent surface finish with minimal machining.

Who are the leading aluminium die casting manufacturers in Gujarat?

Gujarat hosts several advanced manufacturers specializing in aluminium die casting for automotive and industrial applications

Is high pressure die casting suitable for complex designs?

Yes, it’s perfect for producing complex, lightweight, and durable components in large volumes