Aluminium Gravity Die Casting Services in Ahmedabad, Gujarat

At Sejasmi, we are proud to be a leading name in precision casting solutions in Gujarat, specializing in high-quality aluminium gravity die casting. Our advanced facility and experienced team deliver superior components that meet the exact specifications of diverse industries. We are recognized as reliable aluminium casting manufacturers in Ahmedabad and expert aluminium die casting manufacturers in Gujarat, committed to delivering unparalleled quality and efficiency.

Gravity Die Casting is a metal casting process where molten metal is poured into a mold positioned vertically or horizontally, allowing gravity to distribute the metal evenly into the mold cavity. This method is suitable for producing high-volume, complex-shaped parts with good surface finish and dimensional accuracy.

Gravity die casting is capable of producing large quantities of parts, making it ideal for high-volume production runs. The process allows for the production of complex shapes and intricate details, making it a good choice for parts with complex geometries. Gravity die casting typically produces parts with a high-quality surface finish, which can reduce the need for additional finishing operations. The process is capable of producing parts with tight tolerances and good dimensional accuracy, making it well-suited for applications that require precise parts.

Gravity Die Casting Process

Often referred to as permanent mold casting, gravity die casting is a metallurgical process where molten metal, typically aluminium alloy, is poured into a reusable, rigid mold (die) under the force of gravity. Unlike sand casting, which uses expendable molds, gravity die casting uses permanent molds made from materials like steel or cast iron, capable of thousands of production cycles. This method provides superior control over the casting process, leading to more consistent and higher-quality parts.

Applications of Gravity Die Cast Aluminium Components

The robust properties and precision of aluminium gravity die casting make it ideal for a wide array of industries.

- Automotive: Engine parts, brackets, housings, transmission components, and suspension parts where strength-to-weight ratio is critical.

- Aerospace: Structural components and enclosures requiring high integrity and lightweight properties.

- Electrical & Electronics: Heat sinks, motor housings, and electrical enclosures due to aluminium’s excellent thermal conductivity.

- Pneumatics & Hydraulics: Valve bodies, pump housings, and manifolds requiring leak-proof characteristics.

- General Engineering: Machine parts, brackets, and fixtures needing precise dimensions and durability.

Looking for precision aluminium gravity die castings in Gujarat? Contact Sejasmi today to discuss your project and get a custom quote!

Why Choose Sejasmi

Expertise & Precision

With deep metallurgical knowledge and advanced gravity die casting techniques, we deliver high-quality results even for complex projects.

Modern Infrastructure

Our Rajpur facility is equipped with state-of-the-art machines, precision controls, and rigorous quality checks to ensure world-class standards.

Customized & Complete Solutions

From tailored casting designs to value-added services like heat treatment and shot blasting, we provide end-to-end aluminium casting solutions under one roof.

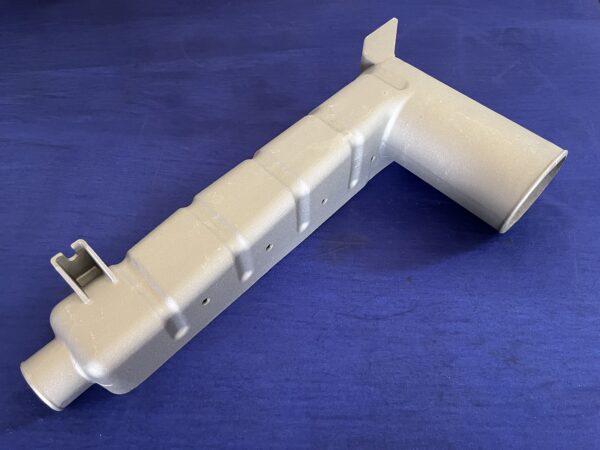

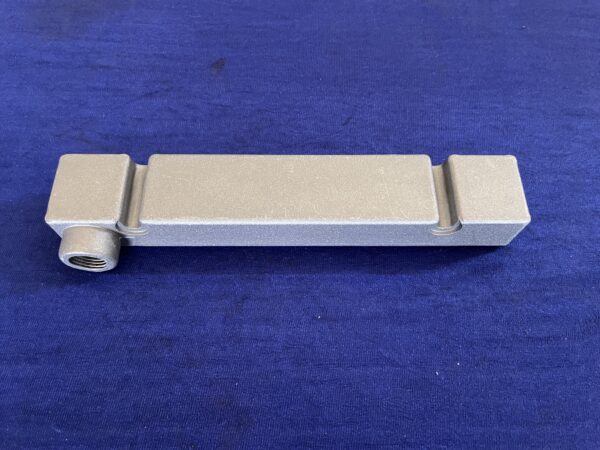

Product Gallery

What is aluminium gravity die casting?

It’s a process where molten aluminium is poured into a permanent mold using gravity, producing strong and precise parts

What are the benefits of aluminium gravity die casting?

It offers excellent dimensional accuracy, durability, and cost-efficiency for medium to high production volumes

Which industries use gravity die casting services?

Automotive, aerospace, electrical, and industrial machinery are the main industries.

Can gravity die casting be combined with other services?

Yes, it can be enhanced with shot blasting, vacuum impregnation, and aluminium heat treatment for better performance.

Why choose aluminium casting manufacturers in Ahmedabad for gravity die casting?

Ahmedabad is home to skilled aluminium die casting manufacturers who provide high-quality parts at competitive costs.